Ultrasonic inspection introduces beams of high frequency sound into the piece. The sound reflected at material interfaces is analyzed to define the presence and location of discontinuities.

Angle beam ultrasonic flaw detection is used to inspect welds using the shear wave mode of transmission to detect welding discontinuities such as linear defects and volumetric defects.

Renu’s Conventional NDT Services

Ultrasonic Testing

UT Advantages :

Dye Penetrant Testing

Penetrant testing – Based on the properties of capillary action, or the phenomenon of a liq-uid rising or climbing when confined to a small opening due to surface wetting properties of the liquid, Penetrant testing is used for finding surface breaking discontinuities on relatively smooth, nonporous surfaces.

PT Advantages :

Magnetic Particle Testing

Magnetic Particle testing is a versatile inspection method used for field and shop applications. Magnetic particle testing works by magnetizing a ferromagnetic specimen using a magnet or special magnetizing equipment. If the specimen has discontinuity, the magnetic field flowing through the specimen is interrupted and leakage field occurs. Finely milled iron particles coated with a dye pigment are applied to the specimen. These are attracted to leakage fields and cluster to form an indication directly over the discontinuity.

MT Advantages :

Radiography Testing

Radiographic Testing (RT) is the method of inspecting materials for hidden flaws by using the ability of short wavelength electromagnetic radiation (high energy photons) to penetrate various materials.

The radiographic film detects the radiation and measures the various quan-tities of radiation received over the entire surface of the film. Discontinui-ties in the material affect the amount of radiation being received by the film through that particular plane of the material. Radiography can be used on most materials and product forms, e.g. welds, castings, composites etc.

RT Advantages:

Permanent record

Hardness Testing

Hardness is a characteristic of a material, not a fundamental physical proper-ty. It is defined as the resistance to indentation, and it is determined by meas-uring the permanent depth of the indentation

Indentation hardness value is obtained by measuring the depth or the area of the indentation.

Positive Material Testing

PMI provides alloy chemistry and grade ID information instantly using a handheld tube-based analyzer without having to transport, alter, or damage the material.

PMI is also used to ensure that the parent material in vessels and pipe spools is composed of the correct composition and once the compo-nent is welded that the correct filler material was used

Crawler Radiography

Pipeline Crawlers are designed to produce high quality panoramic radio-graphs of circumferential butt weld in pipelines from 3” to 72”.

These units are designed and proven, both onshore and offshore, to work as fully self contained, self powered exposure vehicles and all commands are executed from outside the pipeline using a low activity isotope.

Holiday Detection

Holiday Detector Inspection is a method of non-destructive inspection of punctures in organic coating applied on steel. The proposed methods is only used when the coating is electrically insulated. Principle of Holiday Detector Inspection is based on the application of an electrical potential between the metallic support and a mobile electrode positioned at the surface of the coat-ing to be inspected.

The coating being the insulation due to its dielectric fea-tures. A fault in the coating allows the flow of a current between the electrode and the metallic support through the air or water. This current flow is re-vealed through a visual or audible signal. The limit is given by the breakdown potential of the dielectric composed by the coating.

Videoscope Inspection

Bore scope and Videos cope technologies have advanced dramatically when the small-est common diameter was 16 millimeters; the lightest processor included a cathode ray tube (CRT) monitor and a system required a separate and detached light source. The inspection processes are more thorough, efficient, more easily accomplished and more reliable than ever before, given the advances of the core imaging technology. Typical viewing directions, based on application include: side viewing, direct viewing, fore-oblique and retrospective, where a bore scope is actually looking towards the entrance port of the inspection and almost back on itself.

The magnification of the optical system is dictated by the field of view. If the field of view is narrow, the object target magnification is higher and vice versa. System bright-ness is determined by aperture design in the objective and may maximize brightness at a fixed or limited focal range or average the same over a greater depth of field.

Ferritscope

The FERITSCOPE® MP30 is used to measure the ferrite content in the weld part and parent material by the magnetic induction method. A magnetic field generated by a coil enters into interaction with the magnetic components of the specimen.

The changes in the magnetic field induce a voltage proportion-al to the ferrite content in a second coil. This voltage is then evaluated

Ultrasonic Thickness Gauging

UTG, ultrasonically measures the wall thickness of materials such as steel, plastic and also the metal thickness of a painted structure without having to remove the coating .It is ideal for measuring the effects of corrosion or erosion on tanks, pipes or any structure where access is limited to one side.

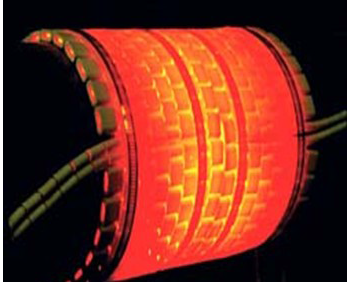

Pre-Heat/Post Heating Services

Heat Treatment is the heating of steel to relatively high temperature (Ex: 590c-700c) shortly after welding and maintaining that temperature for a specific period of time. The purposes is to reduce internal stresses, caused by welding, quench hardening or by cold working .It also has an advanta-geous effect on the elasticity, ductility and strength of the metal.

Types of Heat Treatment Done: